FREEDOM for Draglines

“This [dragline] is the best one we have. It’s easier to run. We have no problems. On the uptime log, this one is in the mid to high 90% range. When you want to run it fast, it’s a lot faster. All of the others are down a day every week or two for maintenance. The 770 is down one day a month. We just run. We are running about two months ahead of schedule. A lot of that has to do with not being down. This machine just digs!”

-

~12%

Efficiency gains

With a DC to AC retrofit

-

80%

Less electrical maintenance

With FLANDERS AC upgrades

-

30%

Power gains

With our M Series motors

Services for draglines

We KNOW draglines, well enough to develop the first purpose-built DC to AC upgrade in the North America. So if you’re looking for dragline service experts, we’re your team.

- Field services

-

Our expert technicians can service any make or model of dragline, new or old, and we’re available for 24/7 troubleshooting. We also offer dragline inspections and audits and can help plan machine overhauls.

-

- Repairs, rebuilds, upgrades

-

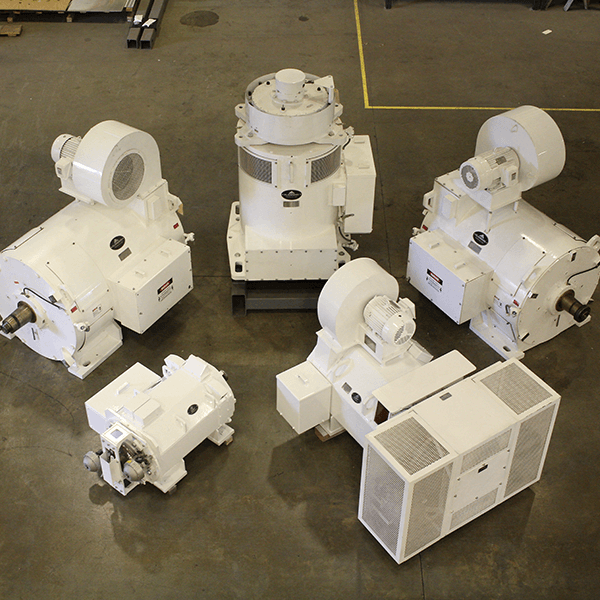

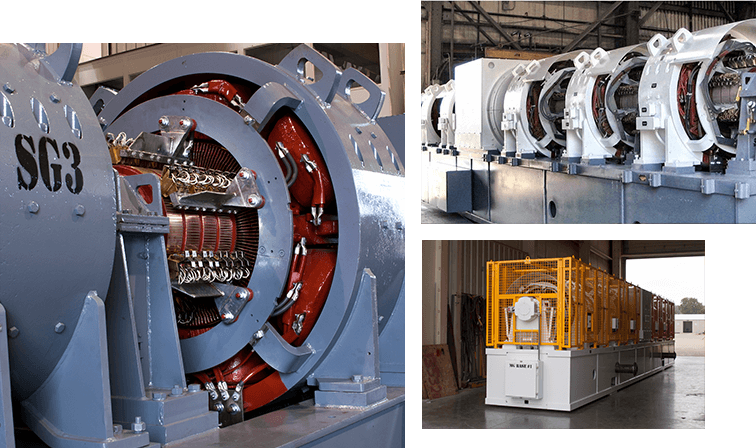

FLANDERS can repair or refurbish your current DC dragline motors, drives, and MG sets; modify them to your specifications; or convert your current DC motor or machine to a modern AC system.

-

- Advanced engineering

-

Informed by decades of repair and field service for mining machines, our team custom engineers everything from automation innovations to replacement motor components for vintage machines.

-

- Custom manufacturing

-

Whether you want a custom AC or DC system or simply need to replace dragline power or control system components no longer in production, we can manufacture whatever you need.

-

-

Our expert technicians can service any make or model of dragline, new or old, and we’re available for 24/7 troubleshooting. We also offer dragline inspections and audits and can help plan machine overhauls.

-

FLANDERS can repair or refurbish your current DC dragline motors, drives, and MG sets; modify them to your specifications; or convert your current DC motor or machine to a modern AC system.

-

Informed by decades of repair and field service for mining machines, our team custom engineers everything from automation innovations to replacement motor components for vintage machines.

-

Whether you want a custom AC or DC system or simply need to replace dragline power or control system components no longer in production, we can manufacture whatever you need.

Our DC to AC dragline retrofit is one of the most significant, practical mining tech advancements of the last decade. DC draglines were OEM standard from the ‘60s into the ‘90s. Now, a lot of those machines are slowing down and approaching retirement at a time when budgets are tight due to market pressures. Extending the life of those draglines by 15+ years, for a fraction of the cost of a new machine? That’s a big deal, especially when you consider the additional productivity, energy savings, and control you get from AC.